Mounting system for PV module on pitched rooftops

PV installations on rooftops are fast becoming an increasingly popular solution for homeowners worldwide. Pitched roofs with tiles on houses or metal sheet roofing on warehouses each need a suitable mounting system to install PV modules safely and efficiently.

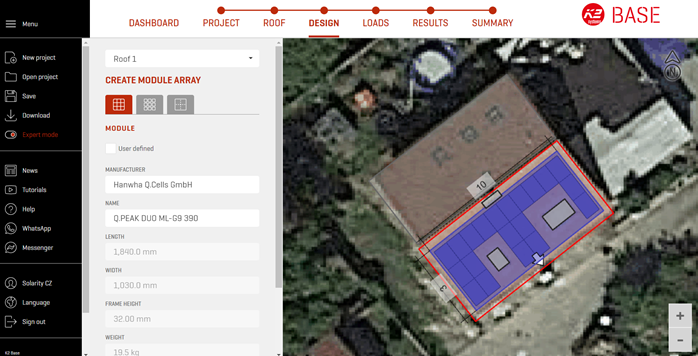

In this article, we will discuss different mounting system solutions for pitched roofs as offered by K2 systems. Beginning in 2004, K2 Systems has developed some of the most pioneering and functional mounting system solutions for photovoltaic assemblies on the global market today. K2 System also provides solutions for installing PV modules on pitched roofs and flat roofs but also ground-mounted alternatives and floating systems.

Roofs with Tiles

The first and most common type of pitched roof concerns family houses with tiled roofs, a very popular model in Europe. On this kind of roof, the mounting structure is fixed on the roof rafters by roof hooks.

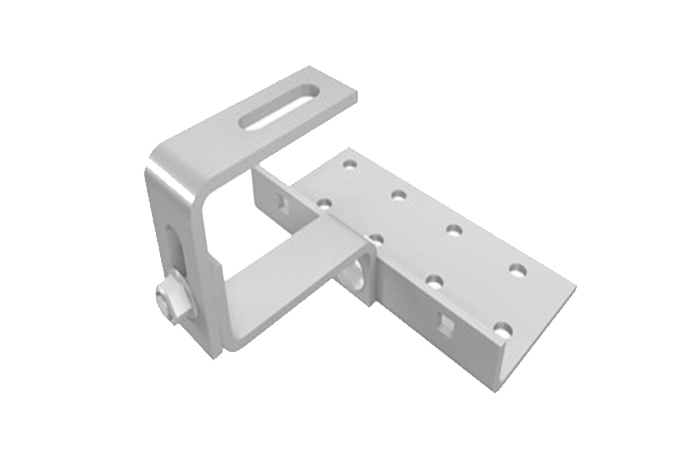

Roof hooks come in many different shapes, types and sizes depending on the exact typology of roof tiles. One of the most utilized roof hooks is the Vario 2, made from stainless steel (EN 1.4016). This hook is highly flexible with 2 joints, which allows the installer to adjust the height straightforwardly in relation to the tile formation.

While planning different mounting systems, the installer must always consider snow and wind load conditions of the location and physical position where the system is ultimately installed. As mentioned, the Vario 2 is both versatile and economical but if the house is situated in regions with high wind and frequent snow the model may not be strong enough to support the system through its full lifespan (around a decade in ideal conditions). K2 has a solution for this though: The Crosshook 4SL made from aluminium EN AW-6063 T 66. This hook is extremely durable while still maintaining the flexibility of the Vario 2.

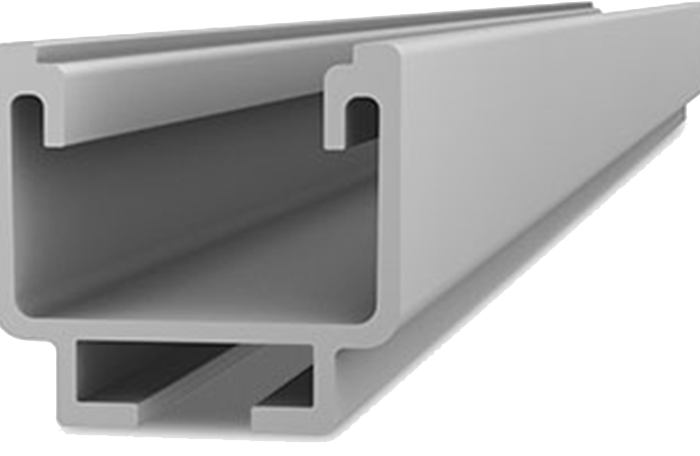

After finishing the hooks, the installer will proceed to fix the rail on it to hold the modules. Both the Vario 2 and Crosshook 4SL is suitable for the SolidRail, which is made from aluminium EN AW-6063 T66. The next step is to attach the hook from below by K2 T-Bolt 28/15 and K2 Hexagon flange nut with serration. Both parts are made of stainless steel A2 (EN 1.4301). The SolidRail is precut to different lengths so that is important for the installer to choose the appropriate length of the rail for their needs and minimize the unnecessary cost of transportation of long rails.

The last items to put on are module clamps to be fixed on the module of the rail. K2 OneMid and OneEnd clamp Universal module clamps are suitable for all SolidRail systems and all popular modules with aluminium frames (30-42mm). These OneMid and OneEnd clamps made from aluminium EN AW 6063 T66. The clamps come with silver and black coating to satisfy the aesthetical requirements of any client.

OneMid and OneEnd clamps

Metal sheet roofs

A popular roofing material is the corrugated or trapezoidal metal sheet shape. Installers usually need to drill through the roof and attach hanger bolts to the wooden or steel substructure of the roof. These bolts are made of stainless steel A2 with an aluminium plate to support the rails and an EPDM sealer to protect from water leakage. On top of the hanger bolt a SolidRail will be set which is similar to the roof hook solution. If the roofing material is thick enough, the installer could fix the mounting system directly onto the metal sheet. For trapezoidal sheets, K2 offers the MiniRail solution as a both robust and economical option. The MiniRail is made of aluminium (EN AW-6063 T66 / EN AW- 6082 T6) with an EPDM sealer on the bottom. An additional MiniFive set could be installed to increase the module tilt angle from the roof parallel to 5 °. This solution provides better ventilation. Solar modules with a (30-50mm) frame are fixed directly to the MiniRail with special MC and EC MiniClamps. These clamps made of aluminium (EN AW 6063 T66, EN AW 6082 T6) come in 2 colors: Silver and black.

For corrugated metal sheets, K2 offers the MicroRail solution which has a similar concept as the MiniRail but comes with a curved CSM adapter to safely seal the roof from water. The MicroRail is also made of aluminium (EN AW-6063 T66 / EN AW- 6082 T6). In this case the installer uses the MiniClamp MC and EC to fix modules to the MicroRail in a manner almost identical to the MiniRail.

One should notice that these MiniClamps cannot be used interchangeably with OneMid and OneEnd clamps.

Further advantages

K2 System also provides solutions for Cable management, module bonding & lighting protection. For seamless workflow, the designer can export the design on the K2 Base to many designing tools from manufacturers like SolarEdge Designer, Fronius, SMA Sunny Design and more. This function allows designers to complete their work quickly and efficiently.

Our offer

As an official K2 Systems distributor Do not hesitate to contact us if you have any queries regarding the choice of the perfect solution for your roof.

There are 2 simple ways to order K2 solutions from us:

Solarity and K2 regularly organize webinars to train prospective installers on how to design and work with K2 solutions properly and competently. Follow us on Facebook and LinkedIn to be updated on these latest webinars and training videos.

K2 systems also provides a warranty for customers. Products under the brand name “K2” will be free of defects in material and workmanship for a period of twelve (12) years from the date of commissioning. Warranty claims can be carried out by phone call or Email. For further information about warranty conditions please check the K2 conditions or even contact K2 directly and interact with their highly attentive customer service.

All our sale representatives have been trained in K2 solutions and Solarity has a technical team ready to help our customers with all specific and unique designs.

What is next?

Posts you might like:

Subscribe to our newsletter

so that you don’t miss any news!