Powering Tomorrow: The Epic Journey of the 10 MWh Battery Project in Hungary

We often talk about the successful launch of massive energy storage projects, but what actually happens between the initial idea and the moment the switch is flipped? The Solarity – Innovart 10 MWh Battery Energy Storage System (BESS) project in Hungary is a story of global collaboration, technical precision, and overcoming complex logistical challenges.

This system, designed primarily to stabilize the grid and participate in the high-frequency aFRR market, is a huge achievement. Here is the insider look at how this cutting-edge system, built by Tecloman, traveled from the factory floor to operational status in Hungary.

Phase 1: The Blueprint (Late 2024 – Early 2025)

Every megawatt begins with a whiteboard and a challenging list of requirements. The project quickly defined its ambition: delivering over 10 MWh of storage capacity spread across two distinct power plants.

The client, Innovart Energia Kft., had specific demands driven by market conditions. While the system was designed for intense use—running at 1.5 cycles per day (equivalent to six hours of charging and discharging daily)—the official government paperwork required documentation based on a more conservative 1-cycle model. The manufacturing and technical teams thus had to engineer the system to meet the real-world performance needs while providing regulatory documentation.

The Power Puzzle

The Hungarian grid operator also mandated an extremely precise system power limit of 4,990 kW. Hitting this exact number was one of the first major engineering challenges. To solve it, the engineers developed a plan to slightly adjust the power factor of the Power Conversion Systems (PCS) to guarantee the 4,990 kW output required for permitting, demonstrating remarkable flexibility in the design.

The Hardware is Chosen

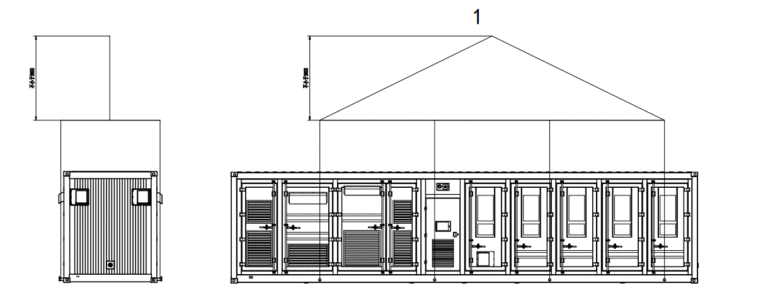

The final design incorporated six containerized units from the Vega series: four large 40-foot containers and two smaller 20-foot containers, combining for a total installed DC capacity just over 10 MWh.

Phase 2: Design Lock-Down and Contract (March – April 2025)

As negotiations heated up in early 2025, technical specifications met commercial reality. The two main sticking points were electrical grounding and aesthetics.

The client initially requested a special IT grounding method for the internal PCS units. The manufacturer, prioritizing the aggressive delivery timeline (which promised commissioning within 147 days of starting production), strongly advocated for their standard TN-S grounding configuration. Ultimately, prioritizing speed was key to the project, maintaining momentum.

On the aesthetic front, details were finalized. The massive containers were commissioned to be finished in a specific light grey color (RAL 7035) and would feature the logo of the owner alongside the manufacturer’s branding.

By early April 2025, the terms were settled. The contract was signed, the Purchase Orders were confirmed, and the 30% advance payment was processed, officially launching the tight production timeline.

Phase 3: Manufacturing, Testing, and Groundwork (Q2 – Q3 2025)

With the contracts signed, the next critical phase—manufacturing—began, typically requiring 90 to 120 business days.

Factory Acceptance Testing (FAT)

The containers and their components, including the high-capacity lithium-ion battery cells, were subjected to rigorous Factory Acceptance Testing (FAT) in China, confirming safety and performance before shipment. This detailed testing, documented thoroughly from June through July 2025, ensured the containers met every safety and operational standard, including grounding integrity, power-on sequences, and fire protection systems.

Preparing the Hungarian Site

While the equipment was built overseas, local efforts focused on foundation work at the Hungarian site. Given the colossal weight of the fully equipped containers (up to 38 tons each), the site required a robust bored piling foundation, constructed using C30 concrete and reinforced steel, specifically engineered to prevent movement and ensure decades of stability. The foundation design included instructions for cable entry and proper grounding connections to the main earthing network.

Phase 4: Delivery and Successful Commissioning (September 2025)

The final race was getting the massive units delivered and operational.

Initially aiming for a late August delivery, the schedule was slightly pushed back. Notification was sent in early September that the new delivery date would be September 17th and 18th. Fortunately, the local team quickly managed to reschedule the heavy machinery, like the crane, needed for off-loading and positioning the equipment.

Upon arrival in Hungary, one critical step remained: the internal battery modules, which are sometimes separated for transport, had to be carefully re-inserted into the containers. This delicate logistics task was estimated to require a forklift and two dedicated workers over a period of three to four days.

Finally, the manufacturing team arrived on site in mid-September to conduct the last crucial step: commissioning and Site Acceptance Testing (SAT). Once the system passed these tests—verifying everything from power control accuracy to remote communication capability—the system was officially commissioned.

The story culminates with the successful set-up of the system, allowing the client to move immediately to configuring the communication links necessary for their external Energy Management System (EMS). This final step unlocks the power of this new 10 MWh asset, ready to trade energy and support grid reliability in the years to come.

Posts you might like:

Subscribe to our newsletter

so that you don’t miss any news!