Commercial Battery energy storage with backup

A battery energy storage system (BESS) is an electrochemical unit that stores energy from the grid and then gives that energy at a later time to provide this energy.

Energy storage in lithium-ion batteries is considered one of the most efficient.

Commercial scale battery energy storage systems for managing electricity supply or providing services for the grid is a new solution gaining popularity. Its gaining popularity results from increasing needs for system flexibility, stability, and predictability for renewable power plants combined with rapid decreases in battery technology costs. As a result, there has been an increase in BESS’s significant role in grid systems in recent years.

And already now, with the development of BESS, various tasks can be solved. One of the tasks of BESS is to provide power loads during blackouts, which we will discuss in more detail in this article.

What is BESS and why it needs to be

A battery energy storage system (BESS) is an electrochemical unit that stores energy from the grid and then gives that energy at a later time to provide this energy.

Energy storage in lithium-ion batteries is considered one of the most efficient.

Commercial scale battery energy storage systems for managing electricity supply or providing services for the grid is a new solution gaining popularity.

What to use BESS for:

- Lack of power from the grid. BESS depends on the type of system, it can – provide energy in response to changes or drops in frequency and voltage and provide additional power in case of insufficient power from the grid. This will help to avoid expensive investments in transmission and distribution reconstruction.

- Energy balance reduces consumers’ overall electricity costs by storing energy during off-peak periods when electricity prices are low for later use and when the electricity prices are high during peak periods.

- With solar (VDE) source

Renewable energy sources are increasingly impacting the country’s power system. Therefore, more significant requirements are being formed for the predictability of such systems. Thus, one option is to add to the solar station, for example, an energy storage system. An energy storage system can help balance the system and avoid surge generation in the grid. - BESS with Backup (grid-off)

Use BESS with backup (off-grid mode) in sites where power outages are frequent or multiple power sources are required.

A backup BESS can also use battery energy to manage consumption compared to a stand-alone system

Let’s consider in more detail the possibilities of using BESS with Backup. Why exactly do we single out BESS with Backup in a separate category? Because an energy storage system does not mean the possibility of grid-off operation in every case. Just as a solar power plant cannot generate electricity without a grid, and in fact, ensuring backup operation is not always necessary.

Systems that can work without a grid are more expensive.

Another challenge is that grid-off systems are quite unique, and previously there was a limited number of solutions that could be applied to the commercial sector. Certain industrial facilities were designed with equipment manufactured specifically for that facility.

With the development and demand for energy storage systems to solve problems in the residential sector, the commercial sector is starting to take this experience and scale it up.

Manufacturers, and developing technologies, have begun to offer energy storage system solutions with the possibility of partial or full grid-off mode.

What is the difference between BESS in the private sector, which is quite common, and the commercial sector? – In scale and responsibilities.

Solutions starting to be used in the commercial sector face new challenges arising from scaling – like fire protection, cooling, thermal runaway prevention, maintenance, etc.

With the development of BES and its various branches, we will soon be able to achieve significant progress in transforming renewable energy sources from non-guaranteed to guaranteed, which will reduce the impact of coal-fired power plants on the environment.

Components and functions of BESS

BESS consists of different parts, the main ones are:

- Battery system

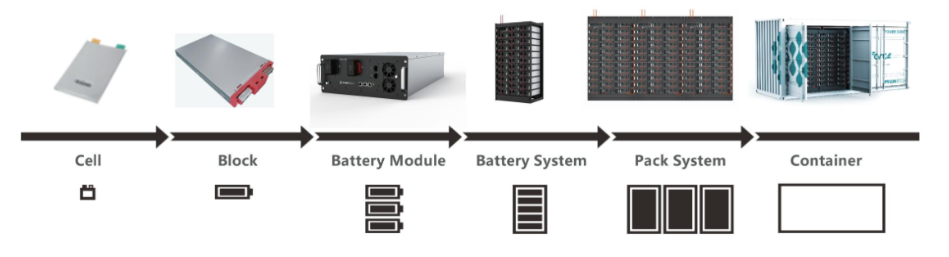

The battery is the main component of the battery energy storage system. The battery stores energy to provide it when needed. A battery consists of lithium cells that form a block, and several blocks connected form a battery module. Several modules connected in serial connections (most often) reach the required voltage as a battery rack. Battery racks are connected in parallel to achieve the required capacity, forming a battery energy system that can be scaled to a packaging system, container, etc.

Depending on the voltage and power required, you combine parallel and series connections to build the system you need to scale

- Battery system

- Battery Management System (BMS)

The lithium battery component of the BESS must be managed by a BMS (Battery Management System). The BMS is the brain of the battery system, whose main function is to protect the battery from damage in various operating modes. The BMS must ensure that the battery is operating within determined ranges for critical parameters, including:- State of Charge (SoC)

- State of Health (SoH)

- Voltage (V)

- Temperature (°C)

- Current (A)

- Battery Management System (BMS)

Controlling such important parameters helps to avoid fire, overcharge, short circuits, imbalance, etc. A properly designed BMS is a vital component of the battery energy storage system and ensures battery safety and long life in any lithium BESS.

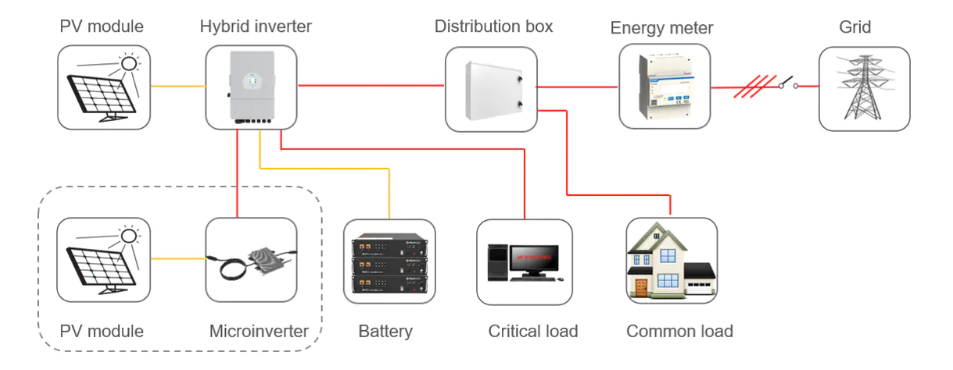

- Power Conversion System (PCS) or Hybrid inverter

BESS stores and gives energy in direct current (DC), but the grid runs on alternating current (AC) like most of the load. To provide energy from the BESS to the grid (loads) and to charge the BESS from the grid, a power conversion system (PCS) or a hybrid inverter is needed. It can be a whole system that is combined from several types of inverters. A PCS or hybrid inverter is more complex than most inverters because it must convert in two directions – from DC to AC and from AC to DC. More complicated PCS systems must be able to charge the system from the grid and feed it into the grid.

The type of the (PCS) or hybrid inverter almost completely determines what tasks the system will perform, whether it will be a system for stabilizing a weak grid or a system with the ability to work in off-grid mode or a system that will provide services for the grid.

The PCS or hybrid inverter has a steady connection with the BESS and takes part in its management. Depending on the settings, it will be controlled to what level, when, and how often the batteries will be discharged and charged.

It is important to know the two types of configurations of the power conversion system. AC-coupled and DC-coupled.

For a Solar power plant with combined BESS, there is a choice between the two. AC coupling is when the BESS is connected in parallel to the solar PV system on the AC side.

DC-coupled is when PV and BESS are connected on the DC side.

- Power Conversion System (PCS) or Hybrid inverter

- Other (generator optional)

Depending on the size of the system and its tasks, BESS may include such systems as heating, ventilation, air conditioning, monitoring, fire suppression, SCADA, etc. It is also possible to single out the quite frequent combination of BESS with renewable energy.

Safety

Lithium-ion (Li-ion) batteries are quite safe and widely distributed. They are used in many electrical devices to ensure their autonomous operation. However, the large battery capacity requires additional attention for maximum safety and long-term system use.

Lithium-ion (Li-ion) battery cells can experience a chemical reaction known as thermal runaway. It does not require oxygen or a visible flame if it occurs within a tightly packed cell assembly. If not addressed by system protection devices, this process can continue to drive up temperature and pressure until the battery cell ruptures, which in turn can release explosive gasses. If thermal runaway propagates tfhrough a module, flammable gasses may build up within the BESS, creating the conditions for an explosion to occur. Thermal runaway can also be caused by exposure to overheating from traditional fires.

It is important to note that a standard approach to minimizing conventional fires such as turning off ventilation and using clean fire suppression agents to cool or starve a fire of oxygen— may worsen the threat of an explosion by allowing explosive gas concentrations to increase. Thus, emergency systems and emergency response protocols should be designed to extinguish fires and ventilate enclosures, as needed, before entry.

We recommend including in your BESS (depending of the scale) the next system (NOTE: All system security measures must meet national standards and be designed by qualified engineers with appropriate certifications):

- Hazard Detection Systems

- Thermal Runaway Prevention

- Fire Suppression

- Ground Fault Protection

- Explosion Study

IMPORTANT DURING BATTERY ENERGY STORAGE SYSTEMS (BESS) EMERGENCIES In the event of damage or fire involving battery energy storage systems (BESS):

- Always assume the batteries and associated components are energized and fully charged.

- Safety Data Sheets (SDS) can provide important information regarding battery chemistry.

- Exposed electrical components, wires, and batteries present potential shock hazards.

- During incidents involving a BESS, responders should follow these steps: IDENTIFY (the location and type of system), SHUTDOWN the BESS if necessary, WATCH OUT for high voltage & other hazards.

- Wear all PPE and look away when operating disconnects to protect against arc flash injuries.

- Locate building personnel responsible for the system and/or locate emergency contact numbers.

- Be prepared to control HVAC systems to prevent the spread of smoke and toxic/flammable gasses.

Maintenance

Proper maintenance, keeping the batteries at the correct temperature, constant system calibration, monitoring, and data analysis will protect against damage and ensure optimal system operation and long life.

The main indicators that need to be continuously observed for successful maintenance:

- It is necessary to maintain the appropriate temperature regime in the room where the batteries are located. High temperatures can damage the battery cells or reduce the remaining cycles. To do this, heat the premises in winter and use air conditioning in summer.

- Make sure the system is properly set up and calibrated. It is important for the system’s proper operation that it works efficiently, such as the parameters of the discharge and charge levels, to prevent discharge below a safe level or overcharge.

- Monitoring and analysis is an important component for effective operation and maintenance of BESS. By monitoring system indicators, its modes, and notifications, it is possible to detect potential threats in time and take measures.

- Regular maintenance is also necessary for the proper operation of a BESS. This includes routine cleaning of the system, replacing worn or damaged components, and performing capacity tests on the batteries to ensure their continued efficient storage capabilities. The system’s inverters can be calibrated to ensure that the BESS is able to efficiently convert the DC power stored in the batteries to AC power. Reducing the auxiliary supply can also significantly increase the efficiency of the system.

What solutions for commercial projects can Solarity offer today?

Huawei – BESS

Huawei BESS can be used to power electrical grids, support the grid’s reliability, and store excess electricity for later use.

This solution can be used to:

- Arbitrage: The system can be used to charge the battery at low energy prices and discharge at higher prices (for example, during peak hours).

- Firm Capacity or Peaking Capacity: System operators must ensure they have an adequate supply of generation capacity to reliably meet demand during the highest-demand periods in a given year, or the peak demand.

- Operating Reserves and Ancillary Services: To maintain reliable power system operation, generation must exactly match electricity demand at all times. Various categories of operating reserves and ancillary services function on different timescales, from subseconds to several hours, all of which are needed to ensure grid reliability.

- Transmission and Distribution Upgrade Deferrals: The electricity grid’s transmission and distribution infrastructure must be sized to meet peak demand, which may only occur over a few hours of the year.

Victron + Pylontech

Deye + Pylontech

Work modes

Subscribe to our newsletter

so that you don’t miss any news!